الوصف

Standard: EN 13398, ASTM D113, AASHTO T51

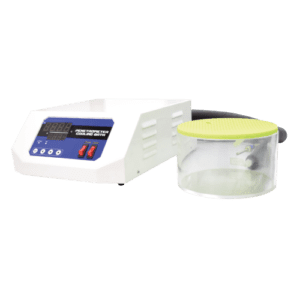

Ductilometer Apparatus, Tension Load

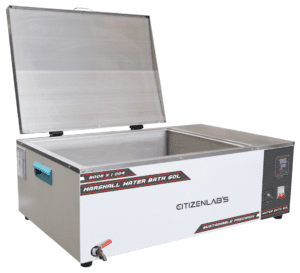

The Ductilometer Apparatus, Tension Load assesses material ductility crucial for construction and engineering. Controlled tensile forces are applied, gradually increasing stress levels to observe the material’s response. Parameters like force and displacement are monitored via the digital interface, enabling precise measurement. This test provides valuable insights into material behavior under tension, aiding in informed decision-making for material selection and design. Overall, it’s a vital tool for ensuring quality and innovation in construction and engineering applications.

Features of Ductilometer Apparatus, Tension (Load Series), Advanced Digital

- 2 speed setting for elongation movement.

- High accuracy LED test parameter.

- Using double ball screw with servo motor for uniform movement.

- Save up to 10 groups’ test results.

- Fitted with an immersion electric heater, coiling coil & circulating pump unit.

- Built-in Mini printer for instant print out 3 groups average test result.

- 1000N (Newton Load Cell with Mould Guide Piece).

Standard: EN 13398, ASTM D113, AASHTO T51

-

EN 13398

This European Standard outlines procedures for testing various properties of bituminous materials, including viscosity, penetration, softening point, ductility, elasticity, and adhesion. Compliance ensures materials meet specified performance requirements and quality standards within the European Union.

-

ASTM D113

Developed by the American Society for Testing and Materials (ASTM), this standard test method specifically focuses on the ductility of bituminous materials. It involves subjecting a sample material to controlled tensile forces to assess its ability to deform without fracturing.

-

AASHTO T51

This test method, established by the American Association of State Highway and Transportation Officials (AASHTO), evaluates the penetration of bituminous materials using a needle under specified conditions. It provides insight into the hardness or consistency of bituminous binders, aiding in material selection for road construction projects across North America.

Test Procedure of Ductilometer Apparatus, Tension (Load Series), Advanced Digital

- Preparation: Get the apparatus ready and prepare the sample material as per guidelines.

- Placement: Securely position the sample in the testing chamber to ensure accurate results.

- Setup: Input necessary test parameters such as speed and temperature into the digital interface for precise testing conditions.

- Start: Initiate the test through the digital interface, ensuring all systems are functioning correctly.

- Loading: The apparatus applies controlled forces to the sample, gradually increasing tension.

- Monitoring: Observe and record data including force and displacement during the testing process.

- Analysis: Utilize software tools to analyze the collected data, providing insights into the material’s behavior under tension.

- Report: Summarize the procedure, results, and any conclusions drawn from the analysis in a concise report.

- صيانة: Perform any necessary maintenance tasks to keep the apparatus in optimal condition for future tests.

Technical Specifications:

| Model Number | NL 2006 X / 004 |

| Max. Carriage Displacement | 1500 mm |

| Displacement Accuracy | 1 mm |

| Temperature Range | 5 – 40°C |

| Temperature Accuracy | ±0.1°C |

| Test Speed | 10 x 50 mm/min |

| Tension Load | 1000 N (Newton) |

| Cooling Power | 1200 W |

| Heating Power | 3800 W |

| Nos. of Specimen Carriage | Standard & 1 with load cell |

| Product Dimension | 2120 (L) x 440 (W) x 970 (H) mm |

| Packing Dimension | 2130 (L) x 5400 (W) x 1200 (H) mm |

| Approx. Product Weight | 158 kg |

| Approx. Packing Weight | 170 kg |

| Power | 220 – 240 V, 1 ph, 50 / 60 Hz |

Unit Consist Of:

| Model Number | Parts Description |

| NL 2006 X / 004 – P001 | 1000N Load Cell Mould Guide Piece |

| NL 2006 X / 003 – P 001 | Handheld Distance Remote Control |

| NL 2006 X / 003 – P 002 | Tank Glass Cover |

| NL 2006 X / 004 – P 002 | Master Controller Board w/Built-in Printer |

*1 Copy of Manual Instruction

Optional Accessories

| Model Number | Accessories Description |

| NL 2006 X / 002 – A 001 | Briquette Mould c/w Base Plate (ASTM D113) |

| NL 2006 X / 002 – A 002 | Briquette Mould c/w Base Plate (ASTM D6084) |

| NL 2006 X / 002 – A 003 | Briquette Mould c/w Base Plate (EN 13398) |

| NL 2006 X / 002 – A 004 | Briquette Mould c/w Base Plate (EN 13589) |

| NL TPR – 57 | Thermo Paper Roll 57mm x 31 mm Dia. (5 rolls / pack) |

المراجعات

لا توجد مراجعات بعد.