الوصف

Standard: BS EN 12697-39, ASTM D6307-10, AASHTO T308-10

Asphalt Binder Analyzer

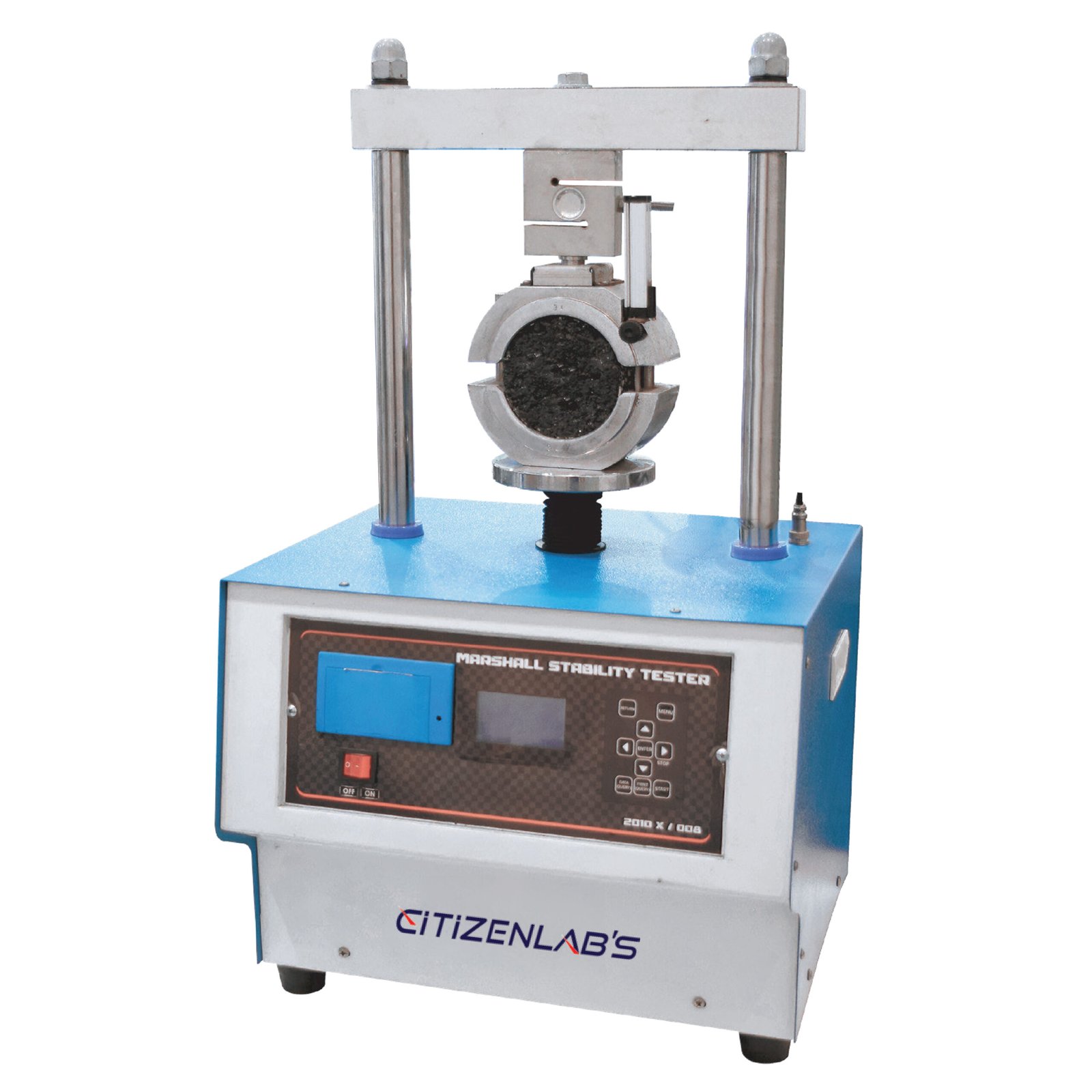

The Asphalt Binder Analyzer is used to perform ignition tests for determining the Asphalt Binder Content of Hot-Mix Asphalt (HMA) and gradation. Measuring the properties of asphalt binders, such as viscosity, penetration, softening point, ductility, and elasticity.

Asphalt binders are the bituminous materials used to bind together aggregates in the production of asphalt pavement. The Asphalt Binder Analyzer operates by heating the asphalt binder in an HMA sample to be burned off in an oven at a controlled temperature above the flame point of the binder. The sample is then subject to specific tests to determine its characteristics under various conditions. Asphalt binder content is then calculated by subtracting the mass of the aggregate remaining after the asphalt binder is burned off from the initial mass of the test sample. These tests help assess the suitability of the asphalt binder for particular applications and ensure compliance with industry standards and specifications in pavement construction.

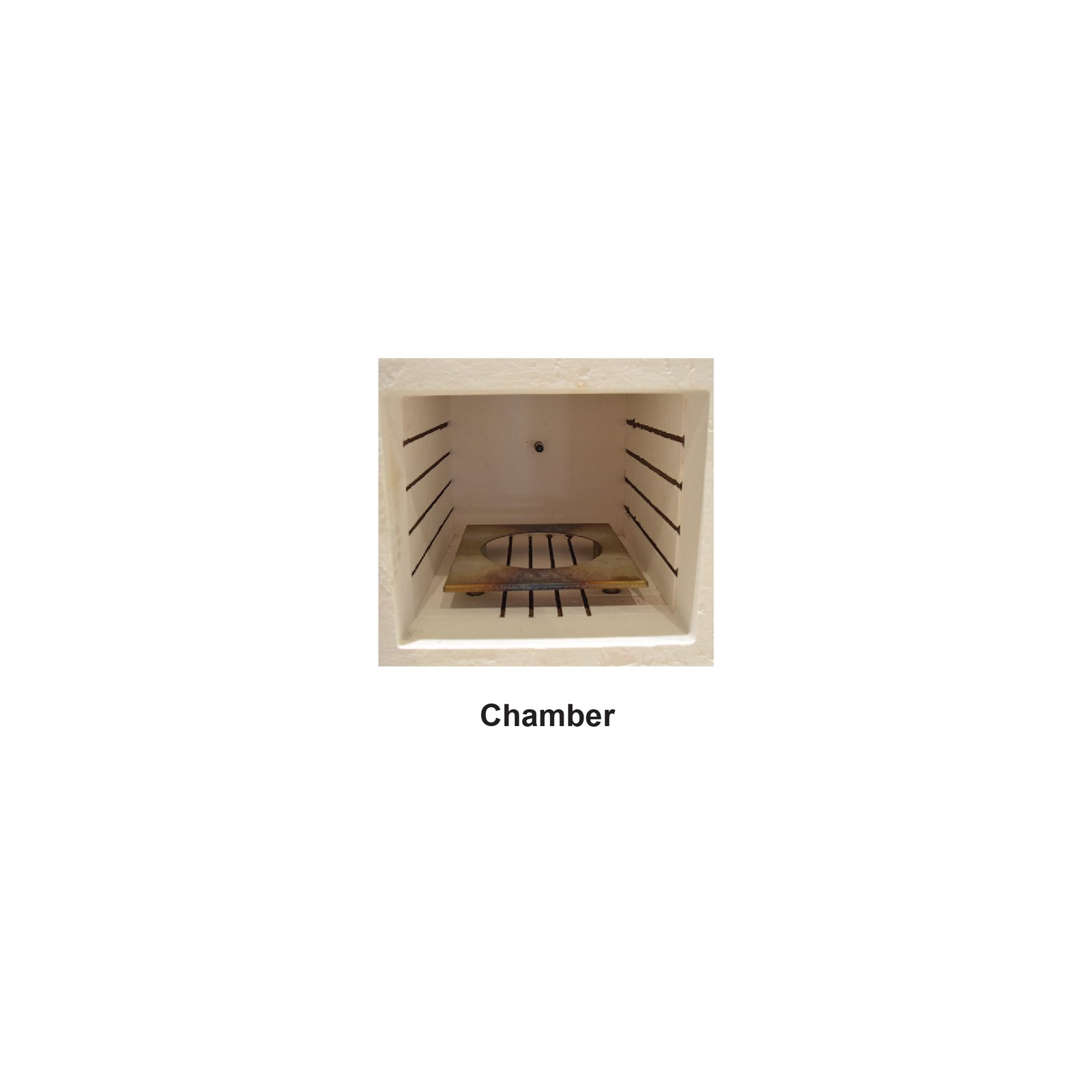

The Asphalt Binder Analyzer integral microprocessor controlled weighing and calculation system is configurable to allow variations to the standard asphalt binder test method. This apparatus combines a sophisticated furnace and weighing system to continuously measure weight loss during combustion, then automatically calculate binder content at the end of the test. Equipped with suitable safety systems to ensure that the furnace door is kept shut during the test.

Features of Asphalt Binder Analyzer

- A large, easy-to-read, backlit digital display updates all data in real-time.

- Independently controlled afterburner with exhaust fan and vent reduces emissions so low that no aspiration hood is needed.

- Automatic temperature control, door lock state detector, door off automatically.

- Active smoke extraction system.

- Improved housing and construction, in continuous operation, low surface temperature.

- Additional base frame storage compartment.

- Optional variety of imported or domestic balance and support internal calibration without removing the balance.

- Automatic storage of experimental data testing

- Turn off the automatic storage of data and experimental data with an automatic print function.

- Can save up to 9 of test data, complete data including test results.

- Automatically generating and saving test results: recalling historical data and printing test reports.

- The temperature control has high precision and good stability.

- Strong electromagnetic compatibility; the heating channel has a soft start function when it is turned on and off and the electric control system has an electromagnetic shielding cover.

- Energy saving; the furnace body is made of thickened high-performance heat insulation materials, which are greatly able to reduce heat energy loss.

Technical Specifications

| Model Number | 2002 X / 002 |

| Maximum Sample Mass | 3000g, recommended sample mass 1200-1800g |

| Weight Detection Accuracy | 0.1g |

| Temperature Control Setting Range | 100 C ~ 800 C |

| Temperature Detection Resolution | 1.0 C |

| Temperature Control Accuracy | 5 C |

| Ambient Temperature | 35 C |

| Power Supply | 380 – 415V, 9.5kW Three-phase four-wire Y connection |

| Combustion Chamber Dimensions | 300 x 250 x 450 mm |

| Dimension (mm) | 850 x 650 x 1250 mm |

| Approx. Weight | 260 kg |

Unit Consist Of:

| Model Number | 2002 X / 002 |

| 2002 X / 002 – P001 | Sample Basket Tray Set (Top Cover, Upper Basket, Lower Basket and Base Tray) |

| 2002 X / 002 – P002 | Extraction Fork |

| 2002 X / 002 – P003 | Extendable Ducting Hose (1 Meter) |

| 2002 X / 002 – P004 | Face Shield |

| 7037 X / 001 | Heat Resistance Glove |

| 7041 X / 006 | Fine Wire Brush (Brass) |

Optional Accessories

| Model Number | 2002 X / 002 |

| 2002 X / 001 – A001 | Storage Compartment |

| TPR – 57 | Thermo Paper Roll 57mm x 31mm Dia. (5 rolls/pack) |

Standards

- BS EN 12697-39: This standard is part of the European Norm (EN) series and is titled “Bituminous mixtures – Test methods for hot mix asphalt – Part 39: Binder content by ignition”. It specifies a method for determining the binder content of hot mix asphalt (HMA) by ignition, where the aggregate portion of the mixture is burned away, leaving behind the binder.

- ASTM D6307-10: This standard is issued by ASTM International and is titled “Standard Test Method for Asphalt Content of Asphalt Mixture by Ignition Method”. Similar to the BS EN standard, it provides a procedure for determining the asphalt content of asphalt mixtures through ignition, where the aggregate is burned off, leaving the asphalt binder.

- AASHTO T308-10: This standard is published by the American Association of State Highway and Transportation Officials (AASHTO) and is titled “Standard Method of Test for Determining the Asphalt Binder Content of Hot Mix Asphalt (HMA) by the Ignition Method”. Like the previous two standards, it outlines a method for determining the asphalt binder content in HMA through ignition.

Test Procedure ofAsphalt Binder Analyzer

-

Sample Preparation: Ensure that the sample is free from contaminants and properly homogenized.

-

Penetration Test (ASTM D5): Determine the penetration of the asphalt binder using a penetrometer at a specified temperature (usually 25C or 77F). Penetration is the depth, in tenths of a millimeter, that a standard needle penetrates vertically into the binder under a known load for 5 seconds.

-

Softening Point Test: Perform the softening point test to determine the temperature at which the asphalt binder softens. Heat a sample at a controlled rate until it becomes soft enough to allow a steel ball to fall a specific distance.

-

Viscosity Test: Measure the viscosity of the asphalt binder at a specified temperature. Common methods include Saybolt Furol viscometer (ASTM D2171) or rotational viscometer (ASTM D4402).

-

Ductility Test: Assess the ductility of the asphalt binder by measuring its elongation characteristics at a specific temperature. Pull a briquette-shaped sample until it breaks and record the length of the elongation.

-

Thin Film Oven Test: Evaluate the effect of heat and air on the asphalt binder by subjecting a sample to specific conditions in a thin film oven. Measure properties before and after the test to assess changes in the binder.

-

Flash Point Test: Determine the flash point of the asphalt binder using a closed-cup or open-cup apparatus. The flash point is the temperature at which the vapor of the binder ignites in the presence of an open flame.

-

Additional Tests: Depending on project specifications or regulatory requirements, additional tests such as elastic recovery, solubility, or specific gravity may be conducted.

-

Data Analysis and Reporting: Record the results of each test. Compare the results with specifications to assess the suitability of the asphalt binder for the intended application.

المراجعات

لا توجد مراجعات بعد.