Description

Standard: EN 12390-1, ASTM C39/C192, AASHTO T23/T126, BS 1881:108

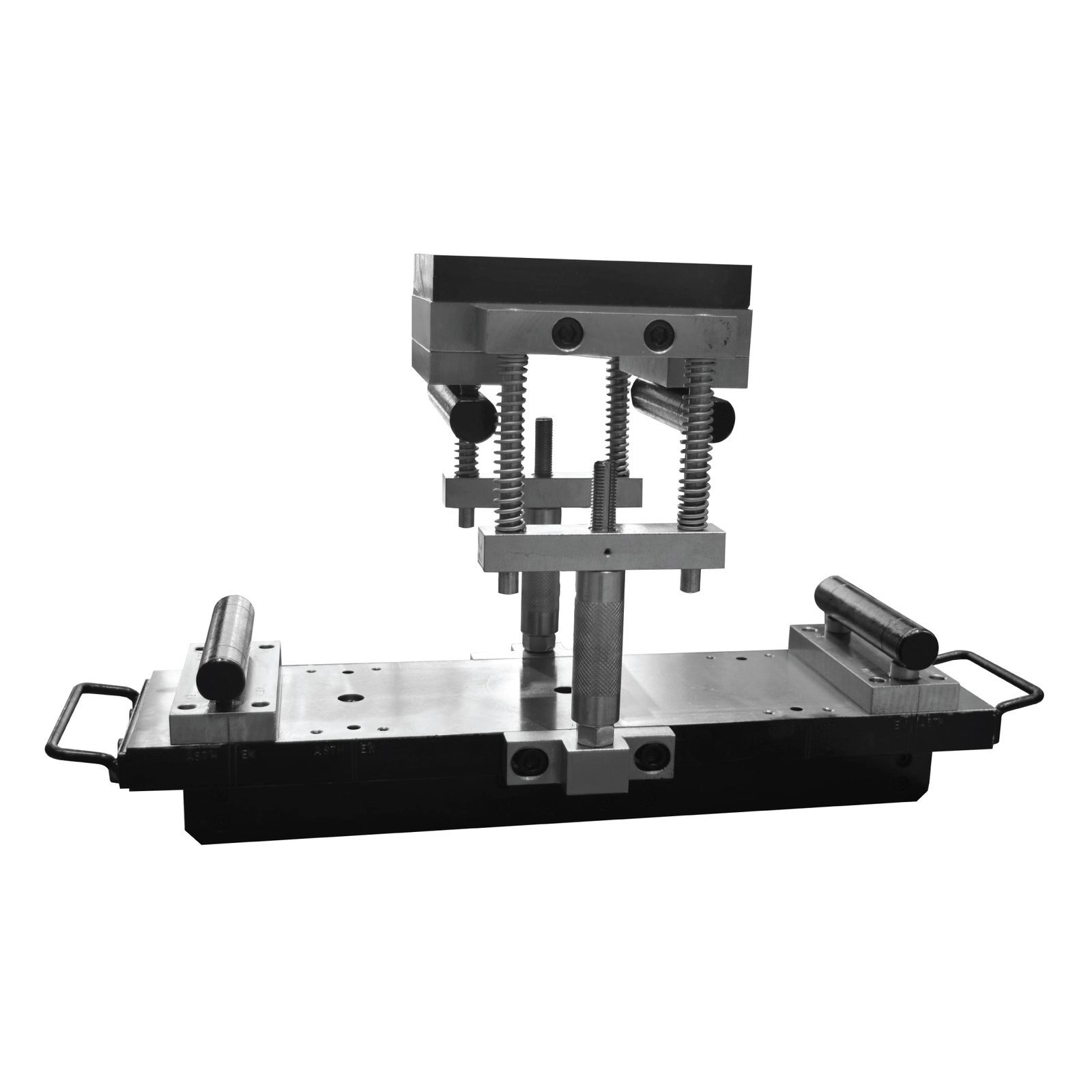

Cast Iron Cube Mould (L-Shape)

100mm Cast Iron Cube Mould with L-Shape, 150mm Cast Iron Cube Mould with L-Shape, creating standardized concrete cube specimens.

Cast Iron Cube Mould with L-Shape is used for creating concrete cube specimens, with mould having two perpendicular arms forming the L shape. Made of durable cast iron, this mould withstands the pressure and weight of the concrete during casting. Its design features two perpendicular arms forming the L shape, with standardized dimensions to meet testing standards. During usage, the mould is assembled, concrete is poured, and allowed to set before disassembly for specimen removal. Common tests include compressive strength testing to determine maximum load-bearing capacity, crucial for quality control in construction projects, and ensuring concrete meets required standards. Overall, this mould is integral to construction and engineering laboratories, facilitating quality control and assessment of concrete properties for various structural applications. The Cast Iron Cube Mould (L-shape) comes in various sizes and weights.

We provide a wide range of high-quality concrete specimens mould such as cubes, cylinders & beams with difference kinds of different sizes. Mould materials such as HEAVY DUTY ABS PLASTIC, HIGH-DENSITY PLASTIC, CAST IRON & MILD STEEL are available.

Features of Cast Iron Cube Mould (L-Shape)

- Made from tough cast iron for durability.

- Available in different sizes to suit different needs.

- Makes it simple to prepare uniform concrete samples.

- Easy to use for engineers and construction workers.

- Helps maintain consistent testing standards.

Standard: EN 12390-1, ASTM C39/C192, AASHTO T23/T126, BS 1881:108

-

EN 12390-1

This European Standard outlines the requirements for testing concrete in structures by covering aspects like, sampling, making and curing specimens, and testing for compressive strength. It guarantees the concrete used meets the required standard for strength and durability.

-

ASTM C39/C192

This standards are established by the American Society for Testing and Materials, while ASTM C39 determines the compressive strength of cylindrical concrete specimens, ASTM C192, on the other hand, outlines the making and curing of concrete test specimens in the laboratory. These standards offer instructions for every step involved in the process of preparing, casting, curing, and testing concrete specimens.

-

AASHTO T23/T126

These standards are established by American Association of State Highway and Transportation Officials. AASHTO T23 depicts the making and curing of concrete test specimens in laboratory, while AASHTO T126 describes the test method for determining the compressive strength of cylindrical concrete specimens. These standards are specifically designed to meet the needs of the transportation and highway sectors, guaranteeing that the concrete utilised in road and bridge construction meets high standards of quality and durability.

-

BS 1881:108

This British Standard outlines the method for making and curing test specimens in the laboratory. It provides guidelines for preparing, casting, and curing concrete specimens to ensure accurate testing of compressive strength. British Standards like BS 1881 are widely recognized and used in the United Kingdom and many other countries, ensuring the quality and performance of concrete materials in construction projects.

Testing Procedure of Cast Iron Cube Mould (L-Shape)

-

Prepare Mould: Clean and assemble the mould securely.

-

Mix Concrete: Prepare the concrete mix as instructed.

-

Pour Concrete: Fill the mould with the concrete mix, compacting it to remove air pockets.

-

Finish Surface: Smooth the concrete surface.

-

Cure: Cover the mould and let the concrete cure for the specified time.

-

Demould: Carefully remove the mould to reveal the concrete specimen.

-

Test: Conduct tests, like compressive strength, on the specimen.

-

Record Data: Keep track of all test results and observations.

-

Analyze Results: Assess the concrete’s performance based on test outcomes.

-

Report Findings: Prepare a report summarizing the test procedures and results.

Technical Specifications:

| Model Number | Items Description |

Dimension (LxWxH) mm |

Approx. Weight |

| 4014 C / 025 | 100 mm Cast Iron Cube Mould (L-Shape) | 230 x 165 x 110 | 8.0 kg |

| 4014 C / 003 | 150 mm Cast Iron Cube Mould (L-Shape) | 285 x 215 x 160 | 15.6 kg |

| 4014 C / DK150 | 150 mm Cast Iron Cube Mould (L-Shape) | 285 x 215 x 160 mm | 12 kg |

Reviews

There are no reviews yet.