Description

Standard: BS 598-102,EN 12697-1

Product Description

The Binder Recovery Apparatus is a device used in asphalt production plants. In asphalt production, a binder, typically asphalt cement, is mixed with aggregates to create asphalt concrete, commonly used in road construction. The binder recovery apparatus is designed to recover the asphalt binder from reclaimed asphalt pavement (RAP). Imagine this, the apparatus recycles an old road and transforming it into a new road. Thus, helping to reduced waste, making sure the environment is protected and cost effective.

Features of Binder Recovery Apparatus

-

Versatile Compatibility with various types of asphalt production plants.

-

Robust Construction with durable materials and components, the apparatus is capable of withstanding the rigors of continuous operation in asphalt production environments.

-

High Recovery Rates of asphalt binder from RAP, maximizing the efficiency of asphalt production and minimizing waste.

-

Environmental Sustainability by reducing the need for new raw materials and minimizing waste generation.

Standard: BS 598-102,EN 12697-1

BS 598-102 – This standard helps to segregate the particular size in the distribution of coarse agregates used in bituminuos mixtures for road constructions. It helps to analyze the right size of particles which is important in assessing the qualtiy and sustainabilty of the agreggates in asphalt mixes.

EN 12697 – This standard focuses on eliminating all the bituminous emulsions in order to recover the binder and also to determine the amount of binder content.

Test Procedure

- Reclaiming the Asphalt Binder: The Binder Recovery Apparatus will be used to consumed the old asphalt pavement material. The apparatus uses methods such as heating and/or solvent extraction in order to separate the old asphalt binder from the reclaimed asphalt pavement.

-

Processing the Binder: Once the separation process is done, the asphalt binder has to undergo further processing in order to elimiate any unwated debries or contaniments. This is to ensure the quality of the binder is up to par and can be used sufficiently in new asphalt mixes.

-

Reusing the Binder: The reclaimed asphalt binder is then being introduced into the new asphalt production process, where it is combined with new argregate material to create new asphalt concrete. This is where it minimizes the use of new asphalt binder which will then reduce waste, ensruing the environment is safe and its cost effective.

Unit Consist Of:

|

Model Number |

Parts Description |

Qty |

|

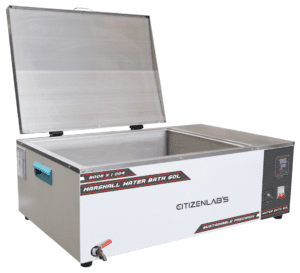

NL 7063 X / 001 |

Digimatic Water Bath |

1no. |

|

NL 7022 X / 001 |

Oil Free Vacuum Pump |

1no. |

|

NL 2041 X / 001 – P 001 |

Rubber Bungs c/w Copper Tubing & Flexible Hose Connector |

1no. |

|

NL 7001 G / 003 |

Round Bottom Flask (250 ml) |

2nos. |

|

NL 2041 X / 001 – P 002 |

Mounting Base |

1set |

|

NL 2041 X / 001 – P 003 |

Pyrex Flask (1 litre) with Rubber Bung & Hose |

1no. |

|

NL 7049 X / 002 |

Retort Clamp 4 Prong |

2nos. |

|

NL 7045 X / 001 |

Boss Head (Small Size) |

2nos. |

|

NL 2041 X / 001 – P 004 |

Ball Valve with Brass Attachment |

2nos. |

Technical Specifications:

| Model Number | NL 2041 X / 001 |

| Approx. Weight | 14 kg |

| Water Bath | 220 – 240 V, 1 ph, 50 / 60 Hz, 750 W, 5 A |

| Vacuum Pump | 220 – 240 V, 1 ph, 50 / 60 Hz, 120 W, 0.5 A |

Optional Accessories:

| Model Number | Accessories Description |

| NL 2041 X / 01 – A 001 | Glass Bit 2 kg – 1 pack |

Reviews

There are no reviews yet.