Description

Solvent Recovery Still

Solvent Recovery Still is used to recycle solvents in Asphalt Extraction Test by extracting pure solvent from both oil and waste materials produced during the extraction process. Heating solvent to vaporize, then condensing it to remove impurities, which allows the solvent to be reused multiple times.

The Solvent Recovery Still consists of a distillation column, condenser, and collection vessel. The solvent-containing mixture is heated, causing the solvent to vaporize. The vapor then rises through the column where it’s condensed back into liquid form by the condenser and collected in a separate container. This process allows for the separation and recovery of the solvent from other components in the mixture, enabling its reuse, which can be both cost-effective and environmentally friendly. Recycling solvents helps to minimize environmental impact by reducing the need for disposal and the production of new solvents. Additionally, it contributes to the sustainability of asphalt production processes.

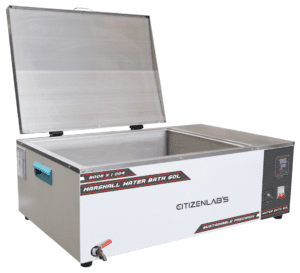

Our new recovery still comes with a cooling circulation tank and it is a moveable type to locate an ideal location. The circulation cooling tank comes with a water circulation water pump. The recovery unit consists of two integral tanks, which are for contaminated solvent and the correction of clean redistilled solvent.

Features of Solvent Recovery Still

- Efficiently recycles solvents from waste solutions.

- Evaporates solvents from solutions, condensing them back for reuse.

- Reclaim solvents cost-effectively.

- Fully stainless steel design (main unit & circulation cooling unit).

- Come with a circulation cooling unit which consists of a circulation cooling unit.

- Overall efficient and compact design.

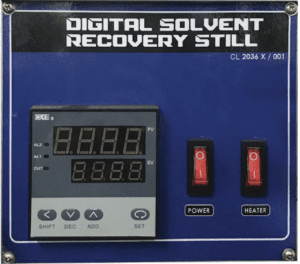

- Digital thermostatic control unit.

- Built-in security devices to prevent overheating.

Test Procedure for Solvent Recovery Still

-

Preparation of the Apparatus:

- Ensure that the solvent recovery still apparatus is clean and properly assembled according to the manufacturer’s instructions.

- Check that all connections, valves, and seals are tight and functioning correctly.

-

Setup and Calibration:

- Set up the apparatus in a well-ventilated area with proper safety measures in place.

- Calibrate any temperature sensors or gauges to ensure accurate readings during the test.

-

Preparation of Solvent Mixture:

- Prepare a known mixture of solvent and any other components that need to be recovered or separated.

- Ensure that the mixture is representative of the actual process conditions.

-

Start-Up Procedure:

- Start heating the mixture in the solvent recovery still apparatus.

- Monitor the temperature and pressure within the apparatus to ensure it remains within safe operating limits.

-

Distillation Process:

- As the mixture heats up, the solvent will vaporize and rise through the distillation column.

- The vapor will then be condensed back into liquid form by the condenser and collected in a separate container.

- Monitor the progress of the distillation process, including the rate of solvent recovery and any changes in temperature or pressure.

-

Collection and Analysis:

- Collect the recovered solvent in a suitable container.

- Analyze the recovered solvent to ensure it meets quality standards and is free from contaminants or impurities.

-

Shutdown Procedure:

- Once the distillation process is complete, shut down the heating and cooling systems of the apparatus.

- Allow the apparatus to cool down before disassembling or cleaning it.

Technical Specifications:

| Model Number | NL 2036 X / 004 |

| Recycling Capacity | 10 L / H |

| Temperature Control Range | 50 – 200°C |

| Heating Power | 1000 Watt x 2 nos |

| Product Dimension (mm) | 780 (L) x 452 (W) x 1280 (H) |

| Packing Dimension (mm) | 880 (L) x 552 (W) x 1380 (H) |

| Approx. Product Weight | 46 kg |

| Approx. Packing Weight | 50 kg |

| Power | 220 – 240 V, 1 ph, 50 / 60 Hz |

Unit Consists of:

| Model Number | Parts Description | Qty |

| NL 2036 X / 004 – P 001 | Recovery Still Unit c/w Funnel | 1unit. |

| NL 2036 X / 004 – P 002 | Moveable circulation cooling tank c/w water circulation pump | 1unit. |

| NL 7048 SS | Stainless Steel Measuring Jug | 1no. |

*1 Copy of Manual Instruction

Reviews

There are no reviews yet.