Description

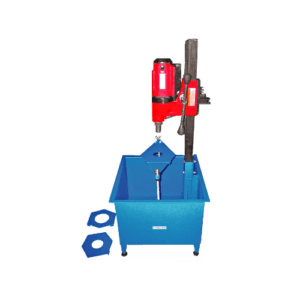

Laboratory Coring Machine

The Laboratory Coring Machine is used to obtain cylindrical samples, or cores, from hardened structures such as concrete, asphalt, rock, or soil. These cores are typically extracted for various purposes, including strength testing, analysis of materials properties, and quality control assessment. The machine consists of a drill bit or coring bit attached to a drilling apparatus, which is then mounted onto a stable platform. The platform often has mechanisms for controlling the drilling speed, pressure, and depth to ensure precise scoring. The core samples obtained are typically of standard dimensions and are carefully handled to maintain their integrity during extraction and subsequent testing. Laboratory Coring Machines are essential tools in construction projects, civil engineering research, and materials testing laboratories, providing valuable data on the structural integrity and characteristics of construction materials.

Features of Laboratory Coring Machine

- Drilling Mechanism that can penetrate through hardened materials, such as concrete, asphalt, rock, or soil.

- Core Collection System to securely capture and extract cylindrical samples (cores) from the drilled material.

- Accuracy and Precision drilling results, ensuring consistency in core dimensions and quality for reliable testing outcomes.

- Safety Features such as emergency stop buttons, protective shields, and automatic shit-off mechanisms to prevent accidents and ensure operator safety during operation.

- Control Panel with a user-friendly interface for adjusting drilling speed, pressure, and depth.

Testing Procedure

- Initial Check: Visually inspect the coring machine for any damages or loose parts and ensure all safety features like emergency stop buttons are working.

- Alignment and Setup: Align and level the coring machine on a stable surface, then set drilling parameters such as speed and depth according to requirements.

- Material Preparation: Materials ( concrete, asphalt, etc.) should be secure to be cored firmly. Ensure the material surface is clean and free of debris.

- Coring Process: Start the machine and begin coring according to set parameters. Monitor for any unusual sounds or vibrations during drilling.

- Core Extraction: Carefully extract the core sample using appropriate tools and handle the core gently to avoid damage.

- Sample Inspection: The core should be inspected for cracks and imperfections. Measure its dimensions accurately.

- Quality Check: Compare the core dimensions with specifications. Do note any deviations and investigate causes.

- Data Recording: Drilling parameters, sample dimensions, and observations should be recorded.

- Maintenance: Perform any routine maintenance tasks as per manufacturer guidelines and do keep a log of maintenance activities.

- Documentation: Document the entire testing procedure and results. Store records for future reference and quality control.

Technical Specifications:

| Model Number | NL 1006 X / 001 |

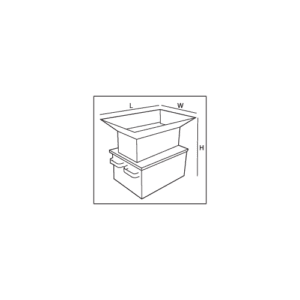

| Tank Dimension (mm) | 800 (L) x 700 (W) x 540 (H) |

| Maximum Coring | Ø 130 mm |

| Stroke Length | 400 mm |

| Speed | 750 r.p.m. |

| Approx. Weight | 70 kg |

| Power | 240 V, 1 ph, 50 / 60 Hz, 1000 W |

Unit Consists Of:

| Model Number | Parts Description | Qty |

| NL 1006 X / 001 – P 001 | Water Tank with Drain Valve c/w | 1no. |

| Clamping Device | 1unit | |

| NL 4006 X / 002 | Coring Machine | 1no. |

Optional Accessories:

| Model Number | Accessories Description |

| NL 7018 X | Core Bit Set (Refer To NL 7018 X Group) |

Reviews

There are no reviews yet.